Common Knife Blades Used For Zund Digital Cutter | Cutting Systems | Flatbed Cutter

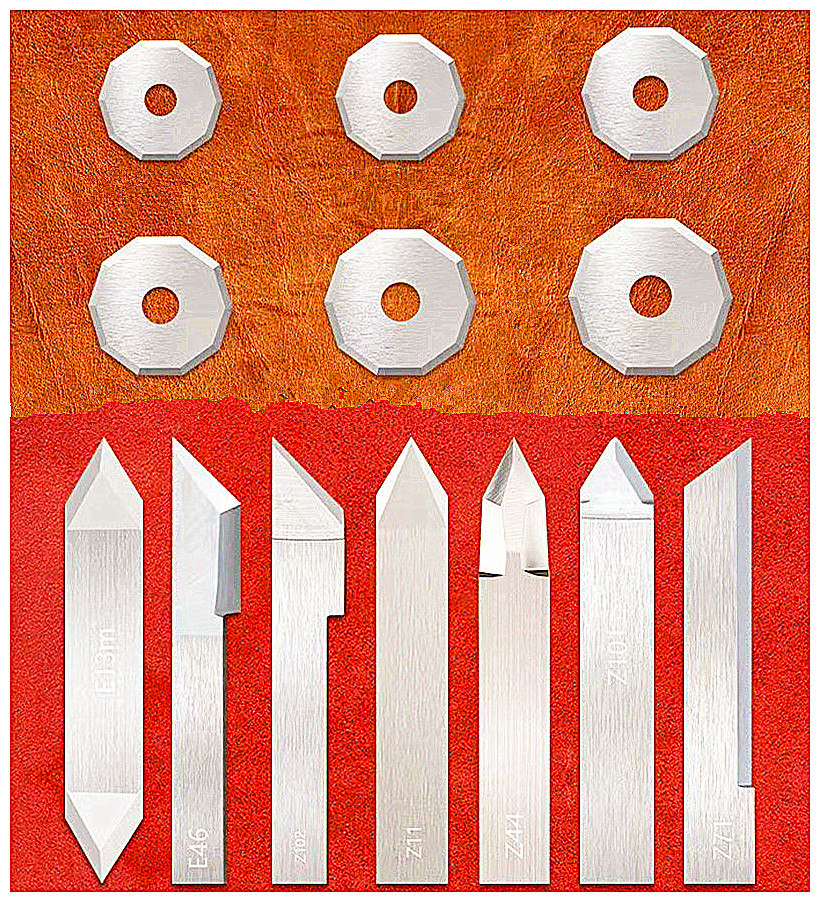

Common knife blades used for Zund digital cutters, particularly in flatbed cutting systems, fall mainly into three categories: drag blades, oscillating blades, and rotary blades. Each type is designed for specific materials and cutting requirements.

Drag Blades

Drag blades are non-powered blades used in tools like UCT, KCT, VCT, SCT, and C2. They are suitable for cutting thinner and flexible materials such as vinyl, paper, cardstock, banners, and thin folding cartons. Drag blades come in round-stock and flat-stock varieties, as well as V-cut blades for creasing and V-grooving.

· Round-stock drag blades: Z1, Z2, Z3, Z4, Z5, Z7. These are ideal for thin and flexible materials like vinyl and cardstock, with Z4 noted for fine blade tips and small overcut for precise cuts up to 2.1 mm depth.

· Flat-stock drag blades: Z6, Z10, Z11, Z44, Z46, Z101, Z102, Z103, Z83. For example, Z46 is a tungsten carbide flat drag blade with a 45° cutting angle and a maximum cutting depth of 20 mm, suitable for heavy-duty cutting of thick materials.

· V-cut blades: Z70, Z71, Z701, Z73, used for precise V-grooving and creasing, especially in display boards and similar materials.

Oscillating Blades

Oscillating blades are powered blades used in EOT/POT oscillating tools, designed for cutting thicker and tougher materials like corrugated cardboard, foam core, rubber, felt, and plastics.

· Pointed oscillating blades: Z16, Z17, Z20, Z21, Z22, Z23, Z28, Z29, Z60, Z66, Z601, Z604, Z606, Z608. For example, Z22 is a robust tungsten carbide oscillating blade with a larger overcut, suitable for intricate and thick material cutting.

· Flat oscillating blades: Z26, Z41, Z42, Z61, Z62, Z63, Z64, Z68, Z69, Z82, Z104, Z201, Z202, Z203, Z204, Z603, Z605, Z607. Z26 is a long oscillating blade for soft, thick materials with a maximum cutting depth of about 8.7 mm.

Rotary Blades

Rotary blades (also called decagonal blades) are used in DRT/PRT tools for cutting breathable materials such as textiles, carbon fiber, and glass fiber.

· Rotary blade models include Z50, Z51, Z52, and Z53.

Examples of Common Blades and Their Applications

|

Blade Model |

Type |

Cutting Angle |

Max Cutting Depth |

Material Suitability |

Notes |

|

Round-stock drag |

Fine tip |

~2.1 mm |

Vinyl, cardstock, thin flexible materials |

Small overcut, precise cuts |

|

|

Z46 |

Flat-stock drag |

45° |

20 mm |

Thick materials, heavy-duty cutting |

Tungsten carbide, durable, precise |

|

Z33, Z35 |

V-cut drag |

45° |

Up to 5 mm |

Display boards, matboards |

High-quality V-cuts |

|

Oscillating |

Pointed |

Up to 22 mm |

Thick, intricate materials like corrugated board |

Tungsten carbide, robust with larger overcut |

|

|

Oscillating |

Flat |

~8.7 mm |

Soft, thick materials |

Long oscillating blade |

|

|

Oscillating |

- |

- |

Carbon fiber, corrugated, nylon, polyester, leather |

Tungsten carbide, long oscillating blade |

|

|

Z50-Z53 |

Rotary |

- |

- |

Textile, carbon fiber, glass fiber |

Decagonal rotary blades |

Shenzhen Oyea Global sales: ensuring availability across Europe, the USA, the Middle East, and Asia with efficient shipping and customer service.Sold To Germany, France, The United Kingdom, Poland, The United States, Russia, Vietnam, Thailand, Indonesia, Singapore, The Netherlands, Switzerland, South Korea, Japan, Turkey, The Philippines, Hong Kong, Taiwan, Italy, Spain, Hungary, The Czech Republic And Other Countries Or Regions

Summary

Zund digital cutters use a wide range of blades tailored to different cutting needs:

· Drag blades (Z1-Z7, Z10, Z11, Z46, Z70 series) for thin to medium materials and precise cuts.

· Oscillating blades (Z16-Z29, Z60 series) for thick, tough, and intricate materials.

· Rotary blades (Z50-Z53) for breathable and fibrous materials.

Choosing the right blade depends on the material type, thickness, and desired cut quality. Tungsten carbide blades like Z46 and Z22 offer high durability and cutting performance for heavy-duty applications, while blades like Z4 and Z33 provide precision for thinner materials and V-cuts.

PREV : Summa Aristo Gerber Esko Roland Zund Knives And CNC Knife Blades Are Widely Sold And Distributed NEXT : Atom Kimla Polska Grupa Cnc Seron Tungsten Steel Blade Compatibility Replacement Applicable